For the fast & efficient repair of small to medium bore pipes across New Zealand, without the need for costly and disruptive excavation.

Get in touch.

For the fast & efficient repair of small to medium bore pipes across New Zealand, without the need for costly and disruptive excavation.

Get in touch.

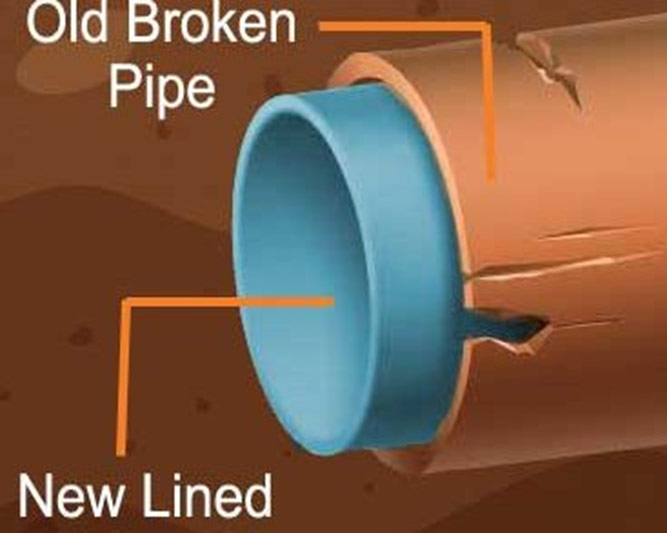

Before you start looking at replacement by the traditional excavation method, you definitely need to consider the new trenchless renewal technology.

Traditional excavation to replace pipes will most likely impact existing structures like concrete footpaths, retaining walls, landscaping, fences etc. This results in a cosly and time consuming project.

Pipe Care Ltd uses CIPP (cured-in-place) Epoxy liners. The liner is ideal for renewing deteriorated, heavily infiltrated, cracked, leaking, or root infested house service pipes without the need for excavation.

In most cases it is roots that cause serious problems in pipelines as they continually grow and expand. Roots restrict the flow until the pipe is completely blocked. It is vital to remove and clean the pipe of any obstructions prior to renewing the pipe by installing a CIPP liner. Pipe Care has root removal equipment that has been developed for this specific purpose over years.

We only need an access point into the pipe on one end of the pipe. The Higley elastic mixture of a polyurethane and PVC coated skin with a polyester felt make it ideal to navigate around multiple bends even as sharp as 90 degrees. The liner offers a smooth finish with minimum wrinkling around bends.

Because of the quality epoxy resin, we use the liner adhesion the host pipe is of outstanding strength characteristics compared to other resin types. A further benefit to epoxy resins is that there are no harmful styrenes released during the curing process.

The liner is impregnated under vacuum and with an impregnation roller station that ensures an even and consistent delivery of the resin throughout the liner length

All our equipment is compact, easy to manoeuvre and reach into hard-to-get places. A small foot-print on site promotes a safer work area, with less disruption to the public or property owner.

We have recently developed several improvements in our work practices that have resulted in benefits in the quality and efficiency of the lining process. The liner is now installed with a removable end cap, which is withdrawn through the liner following final curing. This negates the necessity to use a calibration hose and drastically reduces the installation time.

Not only is it possible to navigate around several 90-degree bends, but it also can be installed over long lengths.

The latest liner material sourced by Pipe Care can now stretch to accommodate changing house connection branch diameters. A continuous liner can be installed even if the house connection branch changes from 100mm to 150mm along its length.

The latest AGILIOS generation has been developed with the goal to perform “Inspections in all situations”. The ultra-light coiler & variable control and placement possibilities offer ergonomic work conditions on all job sites. In built batteries allow inspections without the need of mains cable and give the flexibility to work anywhere.

CCTV inspections are recorded direct to the camera memory and transferred to a memory stick. The footage is stored in MPEG4 format and is supplied to the Principal on a memory stick or via link in the cloud.

This high-pressure water cleaner is specifically designed to solve most problems relating to pipe cleaning – root cutting, unblocking, and removing incrustation deposits.

The unit comes with a 13 HP Honda X390 Engine and a 3650-psi pressure pump at a flow rate of 15 l/min. The low flow rate minimises the amount of water used during the cleaning process.