For the fast & efficient repair of small to medium bore pipes across New Zealand, without the need for costly and disruptive excavation.

Get in touch.

For the fast & efficient repair of small to medium bore pipes across New Zealand, without the need for costly and disruptive excavation.

Get in touch.

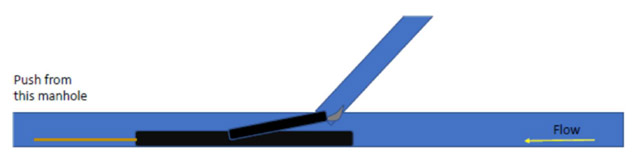

The Latseal consists of a glass fibre composite sock that is saturated with silicate resin. The sock typically extends (covers) up to and beyond the first joint of the house lateral. Installation is a non-disruptive process. The Latseal is installed by accessing the nearest manhole.

The Latseal System has been specially designed to be a simple, fast, and effective Lateral Sealing System. Latseal brings together an Innovative packer, pre-packed Supercil™ resin and a strong, stretchable, glass fibre Liner. A Latseal installation can take place in under 50 minutes.

The controlled bending mechanism inside the lateral arm allows for reliable insertion and withdrawal from the lateral. Latseal packers use an innovative rubber design that allows controlled and staged inflation as well as providing firm pressure on the liner that promotes excellent adhesion. Packer has flow through tubes. No by-pass necessary.

This innovative material provides the dual feature of being both very strong (E Modulus > 3,000MPa) and highly stretchable (>50% diameter change). This means that Latseal seals are both strongly adhered as well as being structurally sound in their own right. Furthermore, the high elongation means that when pressed into place by the Latseal packer, maximum surface area contact is achieved between the liner and host pipe. This is essential to enable the liner to have a high adhesive strength to the host pipe.

Supercil™ resin is a very stable and fast curing resin. The resin is insensitive to Ambient Temperature meaning one resin can be used for all seasons. The resin is Thixotropic for easy and straightforward impregnation. Supercil resin has the unique property in that it is 100% immiscible with water. This means that it does not mix with or get diluted by water.

Supercil resin has superior chemical resistance against most chemicals including harsh industrial solvents. Supercil has been exposed to an extensive list of chemicals. The test reports can be provided from the product’s Technical Guide Appendix B.1

Shrinkage – 0%

Flexural Modulus (short-term) – 10,300 MPa

Flexural Modulus (Long term, 50 year) – 7,900 MPa (Assumed creep ratio of 1.3)

Flexural Strength (Ult

mate) – 110.9 MPa

Flex Strain at First Break – 0.9%

Max Flexural Strain (short-term) – 6.1%

Ultimate Elongation – 2.2 mm

Tensile Strength – 57.3 MPa